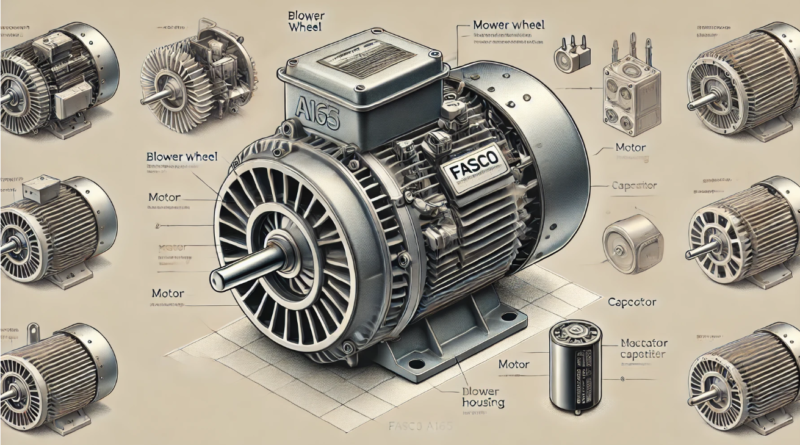

Comprehensive Fasco A165 Teardown Guide

The Fasco A165 is a critical component in various HVAC systems, known for its reliability and efficiency. Proper maintenance and understanding of its internal structure can significantly enhance its lifespan and performance. This guide provides a thorough, step-by-step teardown of the Fasco A165 blower motor, ensuring you can perform maintenance or repairs with confidence.

Introduction

The Fasco A165 blower motor is integral to the efficient operation of many heating systems, particularly in furnaces. Over time, components may wear out or accumulate debris, necessitating a thorough teardown for cleaning or replacement. This guide aims to provide detailed instructions to help you disassemble the Fasco A165 safely and effectively.

Safety Precautions

Before beginning the teardown process, it’s crucial to prioritize safety. First, disconnect the motor from any power source to prevent electrical shocks. Use personal protective equipment, such as safety glasses and gloves, to safeguard against potential debris or sharp components. Ensure your work environment is clean, well-lit, and organized to avoid losing small parts.

Tools Required

To complete the teardown, gather the following tools:

- A flat-head screwdriver and a Phillips screwdriver

- A socket set or adjustable wrench

- Needle-nose pliers

- A rubber mallet

- A soft-bristle brush

- Clean cloths

- A lubricant suitable for electric motors

Having these tools on hand will streamline the process and prevent unnecessary delays.

Understanding the Fasco A165 Specifications

Familiarizing yourself with the motor’s specifications is essential for successful disassembly and maintenance. Below are key details about the Fasco A165:

| Specification | Details |

| Model | Fasco A165 |

| Type | PSC Blower Motor |

| Voltage | 115V |

| Frequency | 60Hz |

| Horsepower | 1/25 HP |

| Current | 0.7 Amps |

| Speed | 3450 RPM |

| Rotation | Clockwise (CW) |

| Bearings | Ball Bearing |

These details are particularly useful when sourcing replacement parts or verifying compatibility with your system.

Step-by-Step Teardown Process

1. Disconnecting the Power Supply

Begin by ensuring the blower motor is completely disconnected from its power source. Double-check this step by testing the unit with a multimeter to confirm no residual electrical energy remains. This precaution eliminates the risk of electrical shock.

2. Removing the Blower Assembly

Locate the mounting screws or bolts securing the blower assembly to the furnace or housing. Use the appropriate screwdriver or socket to loosen and remove these fasteners. Carefully slide the blower assembly out, ensuring not to damage adjacent components or wiring.

3. Detaching the Blower Wheel

The blower wheel is secured to the motor shaft using a set screw or retaining clip. Identify this mechanism and loosen it with the suitable tool. If the blower wheel resists removal, apply a penetrating lubricant to ease the process. Once loose, gently slide the wheel off the shaft.

4. Accessing the Motor Housing

Remove any additional screws or clips that hold the motor housing together. Carefully separate the housing to expose the internal components. Keep track of all fasteners and small parts to ensure a smooth reassembly later.

5. Inspecting Internal Components

Once the motor is open, examine its internal components. Check the windings for signs of wear or damage. Test the bearings for smooth operation and replace them if necessary. Inspect the capacitor for bulging or leakage, as these are indicators of failure. Cleaning and inspecting these parts is vital for ensuring the motor’s longevity.

Maintenance Tips During Teardown

As you disassemble the Fasco A165, take the opportunity to perform essential maintenance. Use a soft-bristle brush to clean dust and debris from components. Apply a few drops of lubricant to the bearings if they are not sealed. Additionally, check for rust or corrosion on connectors and terminals, cleaning or replacing them as needed.

Reassembly Instructions

Reassembling the Fasco A165 involves reversing the disassembly steps. Ensure all components are securely fastened and aligned correctly. When reinstalling the blower wheel, align it properly on the motor shaft and tighten the set screw or replace the retaining clip. Reconnect any wiring according to your notes or photos. Finally, test the motor to confirm it operates smoothly before completing the reinstallation.

Common Issues and Troubleshooting

If you encounter problems during the teardown or reassembly, consider the following solutions:

- Blower Wheel Stuck: Apply penetrating lubricant and gently tap with a rubber mallet to loosen.

- Motor Not Running After Reassembly: Double-check wiring connections and test the capacitor for functionality.

- Unusual Noises: Inspect the bearings and blower wheel alignment; replace damaged components if necessary.

FAQs

- How often should I perform a teardown of the Fasco A165? Regular maintenance every 1-2 years is recommended, depending on usage and operating conditions.

- Can I use standard lubricants for the bearings? It’s best to use lubricants specifically designed for electric motors to ensure compatibility and performance.

- What should I do if I lose a small part during disassembly? Refer to the motor’s parts diagram and order replacements from the manufacturer or a trusted supplier.

- How do I identify a failing capacitor? A failing capacitor often shows physical signs like bulging or leakage and can be tested with a multimeter.

- Is it safe to perform a teardown without prior experience? While the process is straightforward, it’s advisable to consult a professional if you are unfamiliar with motor repairs.

Conclusion

A successful Fasco A165 teardown involves careful preparation, attention to detail, and proper tools. By following this guide, you can efficiently disassemble, inspect, and maintain your blower motor to ensure optimal performance and longevity. Remember, regular maintenance not only extends the life of the motor but also prevents unexpected breakdowns. With the right knowledge, maintaining your Fasco A165 becomes a manageable task, saving both time and money.

Recommended Articles:

- Hari Varsha Hawan Samagri: A Complete Guide to Ingredients, Benefits, and Ritual Usage

- The Ultimate Guide to HeyThereJBaby OnlyFans

- Unveiling the Kmoe EPUB Logo: A Comprehensive Guide for Designers, Developers, and Readers

- GDP Analysis and Casting Blonde: A Comprehensive Guide

- UVS7051 Sensors on Work Wheels: The Ultimate Guide