The Ultimate Guide to ISO 8735 – 5×20 – A-C1 Entl.

Introduction

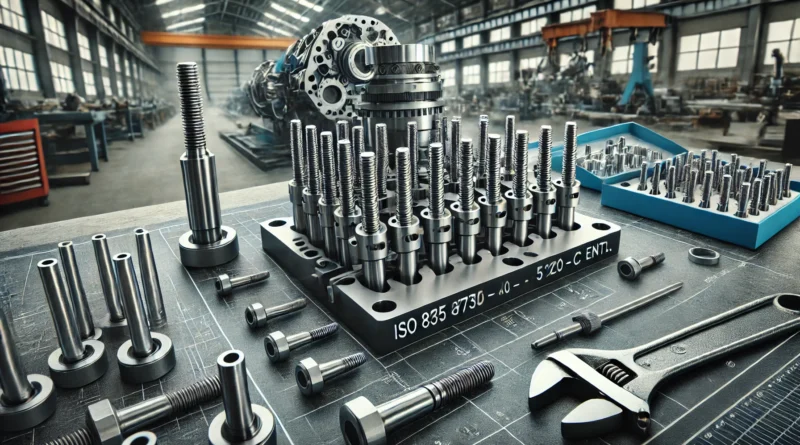

ISO 8735 – 5×20 – A-C1 entl. represents a specific category of dowel pins designed to ensure precision and reliability in mechanical assemblies. These cylindrical pins, featuring internal threads, are essential components in industries where accuracy and durability are critical. This guide provides an in-depth exploration of ISO 8735 dowel pins, offering insights into their specifications, applications, and advantages to help you make informed decisions for your projects.

What is ISO 8735 – 5×20 – A-C1 Entl.?

ISO 8735 is an international standard for cylindrical pins with internal threads, ensuring consistency in manufacturing and functionality. The term “5×20” refers to the pin’s dimensions, where 5 mm is the diameter and 20 mm is the length. The “A-C1” indicates the material classification and hardness level, while “entl.” signifies that the pins have undergone a finishing process to remove sharp edges and internal stresses.

Specifications and Features of ISO 8735 Pins

Breaking Down the Code

- ISO 8735: This standard guarantees uniformity in dimensions, threading, and material quality.

- 5×20: Indicates precise dimensions for specific alignment requirements.

- A-C1: Refers to the material grade and hardness classification, suitable for moderate-strength applications.

- Entl.: A German abbreviation for “entlastet,” meaning deburred or stress-relieved, ensuring smooth operation.

Technical Specifications

| Feature | Description |

| Material | High-grade steel or alloy |

| Hardness | Medium (C1 classification) |

| Finish | Deburred and stress-relieved |

| Threading | Internal threading for screws |

The combination of these features makes ISO 8735 pins ideal for high-precision applications.

Applications of ISO 8735 – 5×20 – A-C1 Entl.

ISO 8735 dowel pins are widely used across multiple industries:

1. Automotive

In the automotive sector, these pins are indispensable for aligning engine components and securing assemblies during production. Their precision ensures proper fitment and functionality.

2. Aerospace

The aerospace industry relies on ISO 8735 pins for critical applications, such as securing fuselage sections and maintaining alignment in jet engine assemblies. The combination of durability and precision makes them a preferred choice.

3. Electronics

In electronics manufacturing, these pins ensure accurate alignment of circuit boards and components. Their reliability minimizes errors and enhances the efficiency of automated processes.

4. Construction Machinery

Heavy-duty machinery requires components that can withstand significant stress. ISO 8735 pins provide the strength and durability needed in excavators, cranes, and other construction equipment.

Advantages of ISO 8735 Dowel Pins

ISO 8735 – 5×20 – A-C1 entl. dowel pins offer several key benefits:

- Precision: Their standardized dimensions ensure exact alignment and fit.

- Durability: High-quality materials and stress-relief processes enhance longevity.

- Versatility: Suitable for a variety of industries and applications.

- Ease of Use: Internal threading facilitates quick installation and removal.

Installation and Maintenance Tips

Proper installation of ISO 8735 pins ensures optimal performance. Follow these steps:

- Preparation: Clean the assembly area to remove debris or contaminants.

- Alignment: Position the pin accurately within the designated hole.

- Fastening: Use a matching screw to secure the pin, ensuring it is firmly in place.

- Inspection: Regularly inspect for wear and replace as needed to maintain reliability.

Maintenance Tips

- Lubricate the pins periodically to reduce wear.

- Inspect for signs of corrosion or damage.

- Replace pins that show deformation to avoid misalignment.

Comparison with Alternative Standards

While ISO 8735 is highly reliable, other standards like DIN 7979 and ISO 8734 also offer cylindrical pins. Here’s a quick comparison:

| Feature | ISO 8735 | DIN 7979 | ISO 8734 |

| Threading | Internal | Internal | None |

| Finish | Stress-relieved | Stress-relieved | Standard |

| Best Use | Precision alignment | Precision alignment | General-purpose |

ISO 8735 stands out for its specific design features tailored to high-precision applications.

Buying Guide for ISO 8735 Pins

When purchasing ISO 8735 – 5×20 – A-C1 entl. pins, consider the following:

- Supplier Certification: Ensure the supplier provides ISO-certified products.

- Material Quality: Verify the grade and hardness to match your application needs.

- Quantity: Bulk orders can often reduce costs.

- Customization: Check if the supplier offers custom dimensions or finishes.

FAQs

Can ISO 8735 pins be customized for specific applications?

Yes, ISO 8735 pins can often be customized by manufacturers to meet specific application requirements. This includes variations in dimensions, threading, and material composition, ensuring compatibility with unique project needs.

2. What is the significance of the “A” material classification in ISO 8735?

The “A” material classification typically refers to high-grade steel or alloy, known for its strength and resistance to wear. This makes it suitable for applications requiring moderate to high durability without compromising precision.

3. What are the common tolerances associated with ISO 8735 pins?

ISO 8735 pins usually adhere to tight tolerances to ensure precise alignment and fit. Typical tolerances include minimal deviations in diameter and length, which are critical for high-precision assemblies. These tolerances are defined in the ISO standard specifications.

4. Are ISO 8735 pins compatible with automated assembly systems?

Yes, ISO 8735 pins are widely used in automated assembly systems due to their precise dimensions and consistent quality. Their deburred edges and internal threading also make them ideal for robotic or machine-driven installations.

5. How do environmental factors affect the performance of ISO 8735 pins?

Environmental factors such as moisture, temperature, and chemical exposure can impact the performance of ISO 8735 pins. Using corrosion-resistant materials like stainless steel and applying protective coatings can mitigate these effects, especially in harsh conditions.

Conclusion

ISO 8735 – 5×20 – A-C1 entl. pins are a vital component in various industries, offering unmatched precision and reliability. By understanding their specifications, applications, and maintenance needs, you can ensure optimal performance in your projects. Whether you’re in automotive, aerospace, or construction, these dowel pins provide a cost-effective and durable solution for alignment and fastening challenges.

Recommended Articles:

- The Ultimate Guide to FictionMania: Everything You Need to Know

- The Ultimate Guide to Ennuifans: Everything You Need to Know

- The Ultimate Sparkspitter Candle Guide: Unlocking its Secrets in World of Warcraft

- The Ultimate Guide to 5starsstocks.com dividend stocks

- The Ultimate Guide to 5starsstocks.com 3d printing stocks